The key component for efficient MD desalination is a suitable hydrophobic membrane with a low resistance to vapor transfer while keeping a high resistance to liquid wetting. These requirements pose a paradoxical issue to the membrane design – large membrane pore size leads to an enhanced distillation capacity, but it also increases the susceptibility to wetting. To date, it remains a challenge to create a polymeric membrane that can simultaneously enhance distillation flux and wetting resistance via a simple processing method.

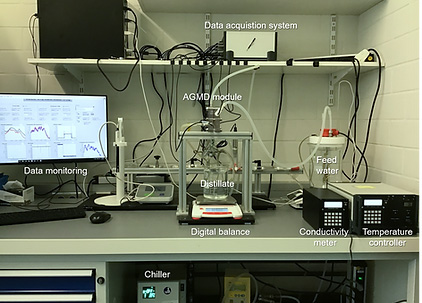

At the AECR Lab, we are currently studying a new approach to creating super liquid-repellent membranes with hierarchical porous structures. By coating a thin layer of silicone nanofilament network on top of microporous membrane matrix, our developed hierarchical membrane showed a concurrent enhancement of the wetting resistance and distillation performance. The nanofilament outer layer can effectively prevent membrane wetting under an extremely high hydrostatic pressure (>11.5 bar) without compromising vapor transport. Meanwhile, the large micro-pores inside the membrane increased the distillation flux by up to 60% over the state-of-the-art commercial membranes. Compared with polyethylene and polytetrafluoroethylene membranes, the nanofilament-coated membrane not only exhibited superior thermal stability in long-term exposure to hot saline but also greatly improve the thermal efficiency in desalination, from 84% to 93%. Our next step is to further develop this novel strategy and enable it to be applied in distributed water treatment systems.